Since its founding in 2015, Nebraska Innovation Studio has served the university community, entrepreneurs and businesses in the state. The makerspace is now catalyzing Nebraska’s robotics ecosystem.

Since November 2023, the University of Nebraska–Lincoln’s makerspace has offered training for programming and operation of collaborative and welding robots. The workshops are open to anyone.

“We have these machines open to anybody and everybody, which is unlike anything else in the country,” said John Strope, program coordinator for Innovation Studio. “We can teach them how to use these machines, and we’ll have a workforce that has these skills, and I think that’s going to be transformative for the region.”

The effort is part of the Heartland Robotics Cluster, which was established following a grant from the U.S. Department of Commerce’s Economic Development Administration in 2022. The cluster is a collaboration of the university, Nebraska Engineering, Invest Nebraska, the Combine, Nebraska Manufacturing Council, Nebraska Extension, Northeast Community College and Metro Community College to expand training, research and implementation of robotics and grow Nebraska’s economy.

Immediately following the grant award, Innovation Studio staff began offering automation workshops and programs for all ages, while they worked to procure next-generation robots for the facility.

“Since the outset of the grant, we’ve been very aggressive with getting equipment and setting up programs,” Strope said. “We’ve had homeschooled elementary students to the OLLI group — all ages — here working with creative automation.”

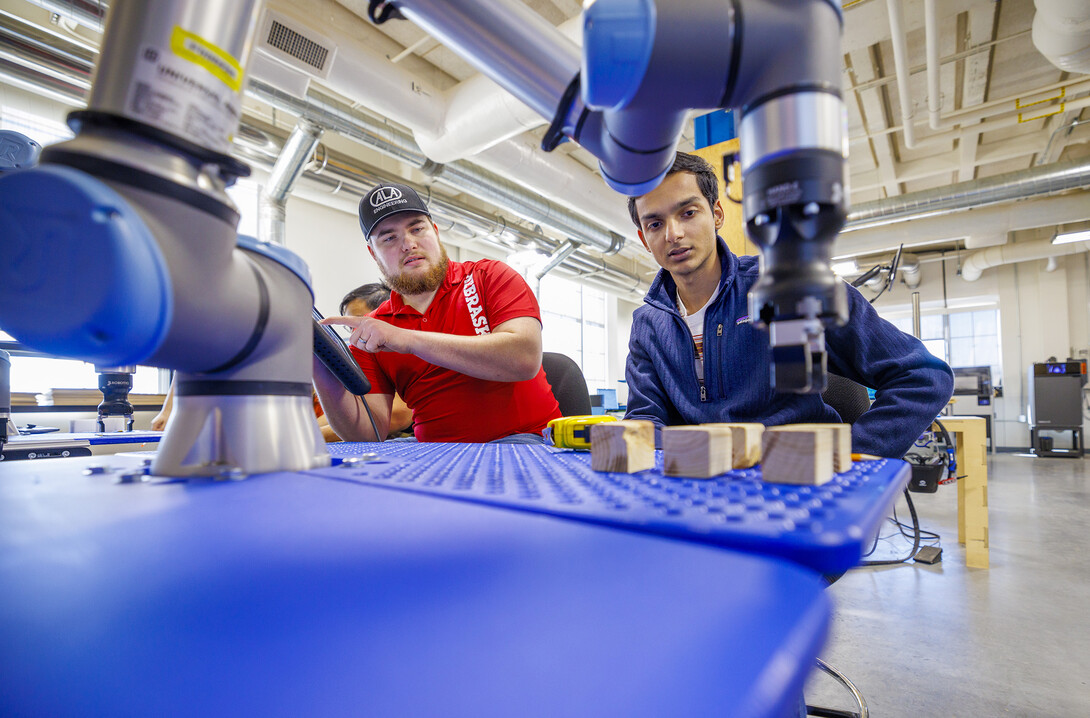

Last fall, following a remodel of the makerspace, two collaborative Universal Robots were installed at NIS, and a welding Universal Robot was added in the metal shop. A third collaborative robot will be added.

A successful pilot robotics training workshop was held with three graduate students in December, and the NIS team began advertising upcoming workshops. Four participants — a student, a community member, an entrepreneur and a manufacturing engineer — joined the Universal Robots CORE Training held Feb. 19-21.

The participants went from having little knowledge to being able to program and run the robots.

“We run them through training over a three-day period, and then they walk away with a core certification that says that they’re comfortable operating, programming and troubleshooting the machine,” Strope said. “It’s a dense few days, but it is remarkable how much is learned in that time.”

Strope said the CORE training is specific to Universal Robots but that the knowledge and skills will transfer to other brands and models.

Jacob Hansen, chief technology officer of Aulick Industries and co-founder of ALA Engineering, participated in the workshop after hearing about it from NIS staff. The companies are startups in manufacturing and the development of autonomous feedlot trucks. He signed up for the workshop because he wanted to see if robotics could be an addition to the manufacturing operation.

“It is easy to train in the programming,” he said. “This showed me that it does make sense to put this on the shop floor, and we could very quickly use them in production.”

Robotics are already a major part of manufacturing across the United States, but having this training and certification available to Nebraskans is a boon, Strope said.

“In the manufacturing environment right now, it’s tough, and it’s going to get worse,” Strope said. “The American Welding Society predicts a shortfall of 360,000 new workers by 2027. To have this available, where someone can learn and become certified in running a welding robot, is huge. You can take the skills of one person, bring in a machine like this and that one person translates to the labor of 10 or more. It’s an absolute no-brainer.”

Finding workers can be challenging in Nebraska, where the unemployment rate is 2.3%. Robots are often employed to do the monotonous or dangerous work that employees don’t want to do. That can make companies more competitive in hiring workers, Strope said, and make Nebraska more competitive overall.

Hansen, whose companies have offices in the Rise Building at Nebraska Innovation Campus, was impressed that he had access to training like this right next door.

“For the University of Nebraska–Lincoln to have programs like this really just shows how big of a focus there is on workforce development here and the next generation of industry,” he said.

Future workshops are being planned, including a CORE training in April. More information about robotics programs and training can be found online.