Husker scientists and staff are formalizing existing research and outreach in precision agriculture into a strategic initiative called NFarms. The effort, in collaboration with producers and industry, will refine and expand precision ag capabilities crucial to boosting farm efficiency and environmental sustainability.

University of Nebraska–Lincoln faculty pursue a range of precision ag work on 3,000 acres of the university’s Eastern Nebraska Research, Extension and Education Center near Mead. Those efforts will be channeled into NFarms to facilitate strategic coordination and maximize the outreach and benefits.

NFarms will be a test bed for new technologies, as well as platforms to help farmers better harness data. The initiative also will develop innovative decision-making tools producers can use for efficient field management.

Think drone- and sensor-enabled operations that lift productivity and resilience to new heights. Plus software solutions that provide cloud-based ag data storage and data analytics. Plus nitrogen management innovations and ag robotic breakthroughs.

“NFarms provides a real opportunity as a technology hub integrating the farm system,” said Joe Luck, professor of biological systems engineering and associate director of ENREEC. “We have a real-world environment to test these technologies and show producers how they’re going to impact their operation.”

To buttress that work, the university in 2024 will break ground on an NFarms facility that will house precision ag technologies. Construction is expected to be complete in the summer.

The university’s precision ag work at the Eastern Nebraska Research, Extension and Education Center operates under real-world conditions, on a scale similar to that of actual working farms. The cutting-edge research involves both irrigated and dryland fields.

NFarms will provide private-sector opportunities. As the initiative advances, companies and entrepreneurs will be able to use the precision ag resources to test innovative ideas for new methods, products and services.

NFarms is unique from other university research facilities in the United States because the site far exceeds in size what any other university has for precision ag research, said Doug Zalesky, ENREEC director. Another plus is the similar commercial scale of the university’s Klosterman Feedlot Innovation Center, also to be built at ENREEC. In all, the center has a total of nearly 10,000 acres for ag research.

“I don’t think you would ever find another single research center in the United States of this size, with both crops and livestock,” Zalesky said.

The breadth and sophistication of the center’s research produce a range of findings with practical importance for Nebraska ag producers. “We have a lot of research here we need to integrate into production operation systems to really see the benefit,” Luck said.

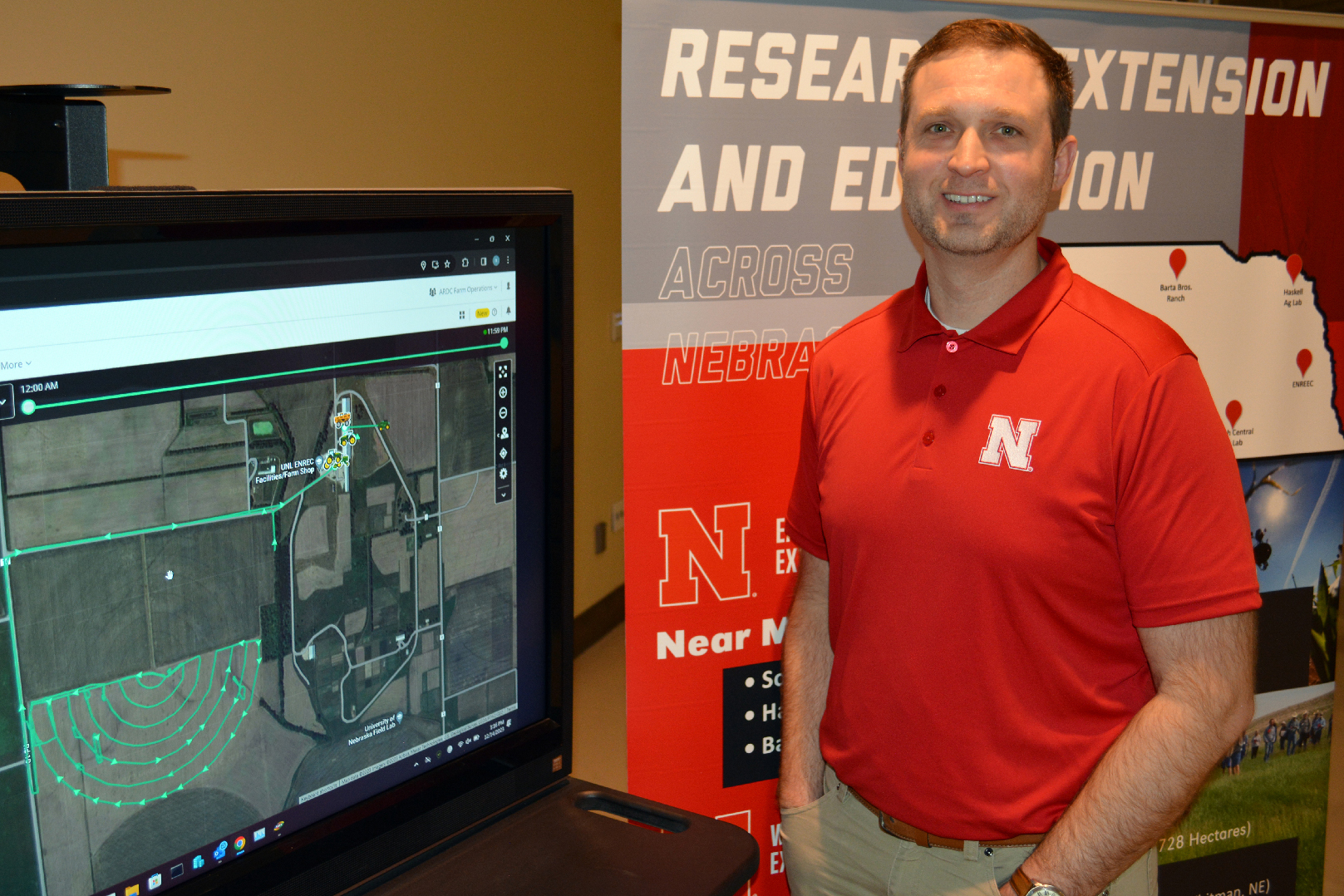

Ag technologist Nate Thorson, research manager for NFarms, points to pesticide application as a key example of how NFarms can enable significant efficiency improvements. At present, checking when it’s safe to re-enter a field can be a cumbersome, inefficient process involving paper records and phone calls to coordinate with colleagues.

But through the high-speed wireless system that NFarms will create, a producer can log into a browser within 10 or 15 minutes after the field was sprayed and obtain re-entry information without any human-error risk, Thorson said.

“This is practically real-time data sharing of facts,” Luck said. “Think about all the inefficiencies you’re cutting out.”

The U.S. Department of Agriculture’s plans to build a regional ag research facility at Nebraska Innovation Campus will provide opportunities for ongoing collaboration with NFarms. That federal facility will greatly increase the number of USDA Agricultural Research Service scientists in Nebraska, and they will be focusing on precision ag technologies. The Eastern Nebraska Research, Extension and Education Center can provide a major venue for their field research.

ARS scientists “will want somewhere to work on those topics, and ENREEC can be the prime real estate for them,” Luck said. “That’s a huge opportunity for us.”

Such high-level collaboration between the university and USDA offers the possibility that Lincoln could ultimately become the nation’s ag data hub.

To communicate its findings as a research proving ground, NFarms can draw on its partnerships with the university’s On-Farm Research Network and Nebraska Extension, plus its work with commodity associations and private-sector companies. An external advisory board will advise NFarms on producers’ real-world needs and serve as a conduit for sharing information about NFarms’ work.

A key aim for NFarms is ag-focused software development, with the ultimate goal of data standardization and efficient cloud-based data storage. Thorson brings valuable expertise in that regard, given his knowledge of agricultural production and software design — a rare combination.

At present, each ag equipment manufacturer uses its own software format. As a result, a producer’s field data is stored in disjointed, disconnected fashion. Over time, NFarms’ software work will aim to bridge that divide, achieving much-needed standardization and opening important new opportunities for managing and analyzing field data.

“We’ve got the expertise to understand the different techniques that can be applied to create innovative solutions” on ag data standardization and management, Luck said. “That’s where our strength is. The impact of that is going to be pretty important as more and more equipment becomes semi-autonomous or autonomous, and you start to look at how much data can come from a field.”