More than $1.4 million in funding from the U.S. Department of Energy will allow two College of Engineering teams to expand innovative energy-related research in partnership with national laboratories.

The Department of Energy recently announced $21 million in funding for 29 new projects through the Established Program to Stimulate Competitive Research. The University of Nebraska–Lincoln is one of only four institutions to have two projects chosen for the funding program.

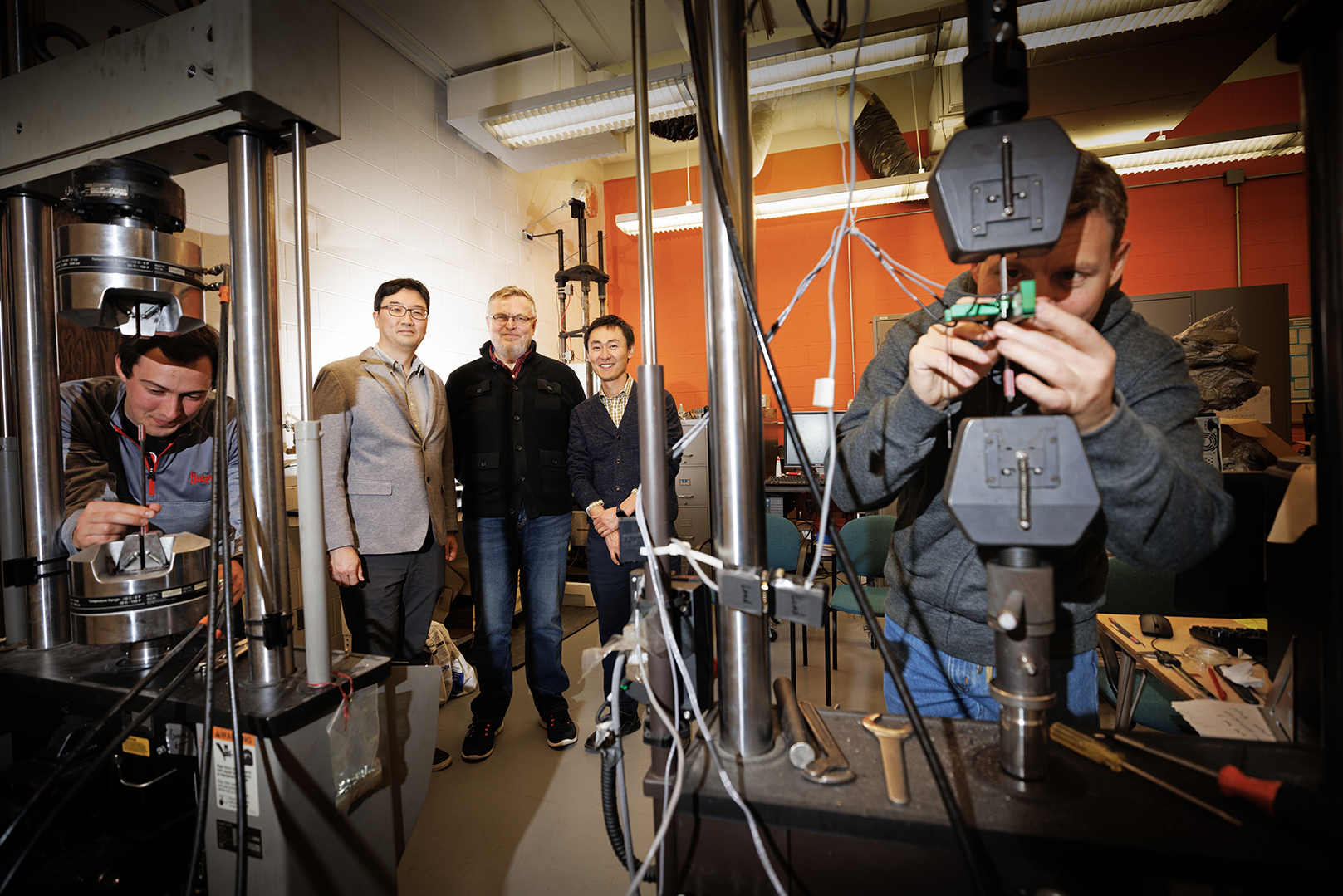

Jongwan Eun, associate professor of civil and environmental engineering; Seunghee Kim, assistant professor of civil and environmental engineering; and Yuris Dzenis, R. Vernon McBroom Professor of mechanical and materials engineering, received $675,000 over three years to investigate how inorganic microfibers can make a more resilient barrier material to improve the long-term storage capabilities of vessels that contain high-level nuclear waste and spent nuclear fuel.

Peter Sutter, professor of electrical and computer engineering, and Eli Sutter, professor of mechanical and materials engineering, received $747,387 over three years to study new classes of semiconductors for use in photovoltaics and information processing.

“We have worked hard to become leaders in the field of layered two-dimensional semiconductors and have developed advanced electron microscopy techniques to be able to study them,” Peter Sutter said. “The grant provides an opportunity to deepen our partnership with Oak Ridge (National Laboratories) that opens access to new capabilities and to unique sources of expertise.”

The Sutters’ new project is built on previous research in which they developed approaches for synthesizing new classes of layered semiconductors, as well as for joining them in engineered “heterostructures” with atomically precise boundaries, or interfaces.

The new research, Peter Sutter said, builds on those advances to address new challenges, such as transitioning to complex systems that combine different functionalities — the absorption of light and efficient separation of light-induced charges at interfaces in devices, for instance. The Sutters are also focusing on electron microscopy techniques that can overcome a limit to measuring the interaction of semiconductors with light.

“With ordinary approaches, one can see or probe light-induced phenomena down to the order of the wavelength of the light, which is only a fraction of a micrometer,” Peter Sutter said. “If we want to go to much smaller scales — ultimately down to the atomic scale — traditional methods don’t work. Understanding these processes are of great importance to fields such as solar energy conversion and quantum information processing.”

In a previous project funded by the Department of Energy, Eun and Kim worked with researchers at Sandia National Laboratories to find materials that improve the deep geologic disposal and storage of spent nuclear fuel.

Adding microfibers to bentonite can create a more durable material that minimizes cracking generated by the high heat of spent fuel inside a canister drying the material on the outside.

The new study, Eun and Kim said, strives to better understand the mechanical properties of the material as a foundation for developing new and improved barrier materials, especially amid extreme soil conditions such as drought.

“We know that dry soil is not favorable to contain these materials, which have to be stored safely for 10,000 years or so,” Eun said. “Cracks can lead to leaking, and that is dangerous. That’s why we need to understand the interactions of multiple elements, like the mechanical characteristics of a fiber-bentonite mixture and the surface energy between bentonite clay particles and the fibers, that will lead to developing better materials.”

Kim said: “We are the first group to add this inorganic fiber to reinforce the bentonite, and we found a good outcome — it can lead to less cracking. We know Nebraska and the United States depend highly on fossil fuels to produce electricity. This grant is very much aligned with the Grand Challenges set by the university, especially in finding more resiliency in our energy systems and working toward decarbonization and a smaller carbon footprint.”