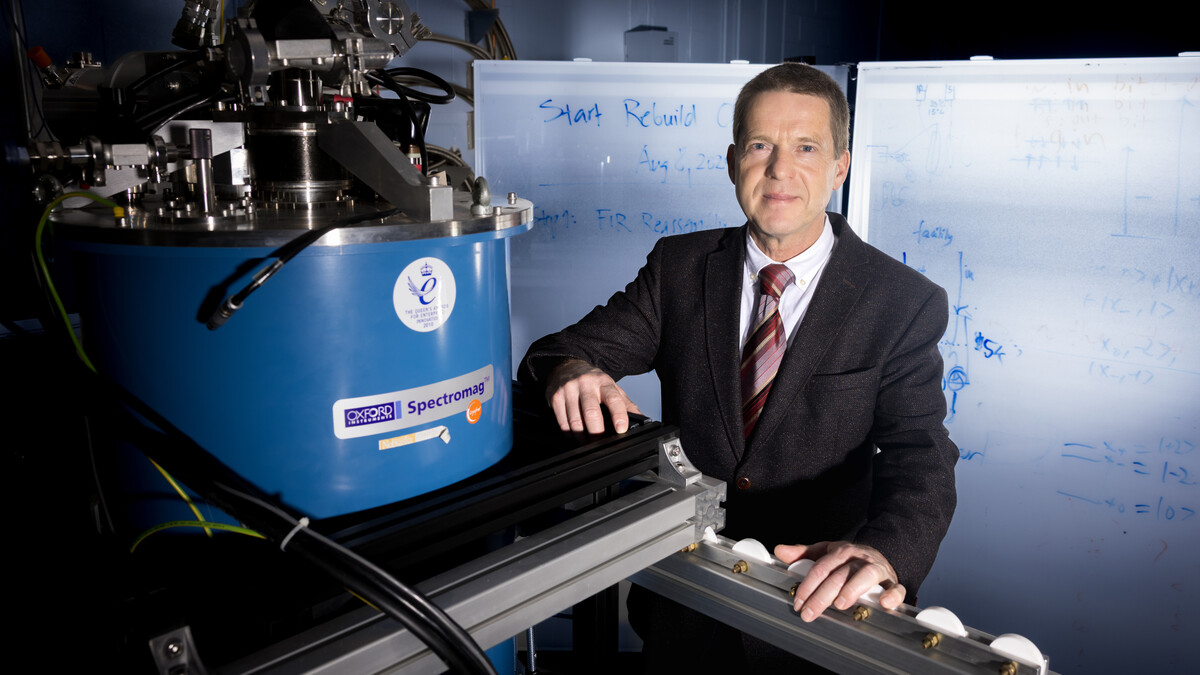

For roadside safety engineers and research groups, which often face limited budgets and resources, collecting complete and contemporary vehicle data is a challenging task. The Midwest Roadside Safety Facility at the University of Nebraska–Lincoln is the recipient of a significant data donation from Caresoft Global, a vehicle data benchmarking organization that is offering a database of detailed vehicle data for electric vehicles to further roadside safety research.

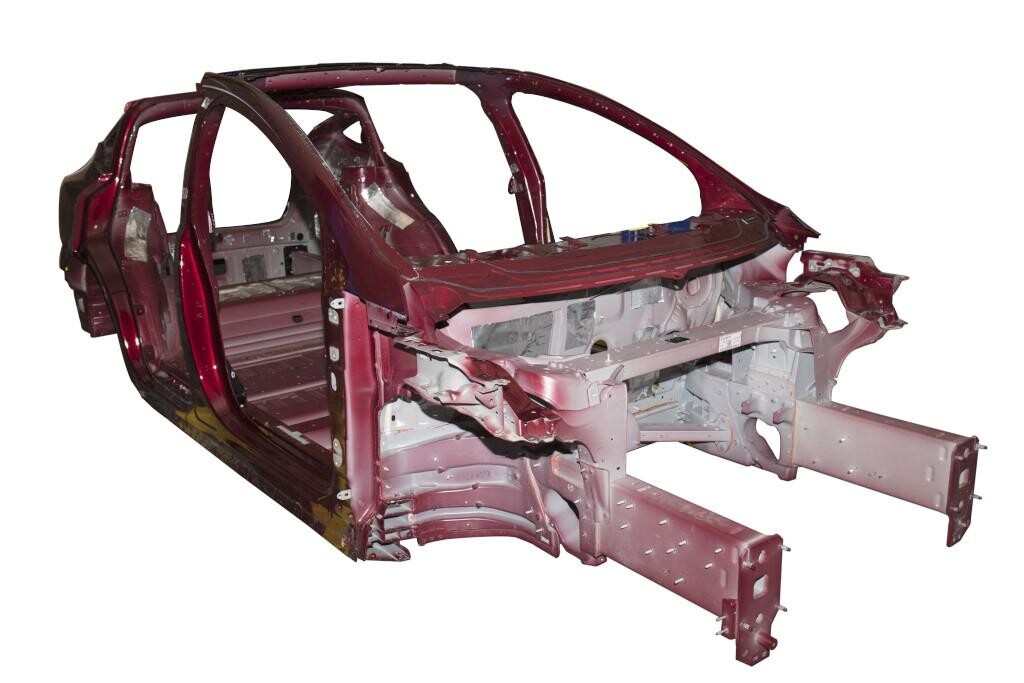

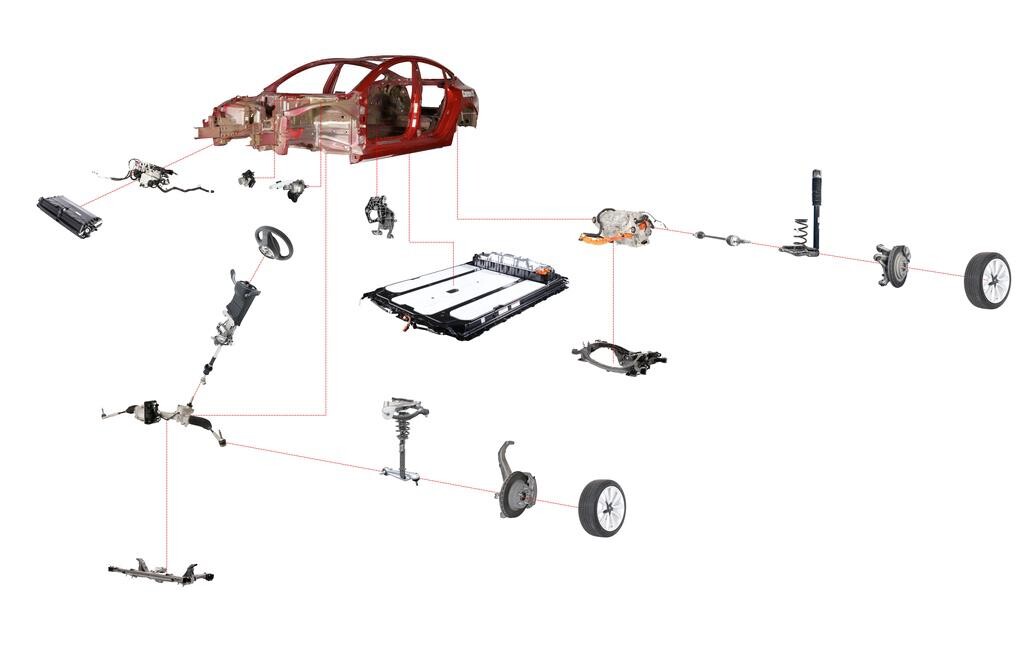

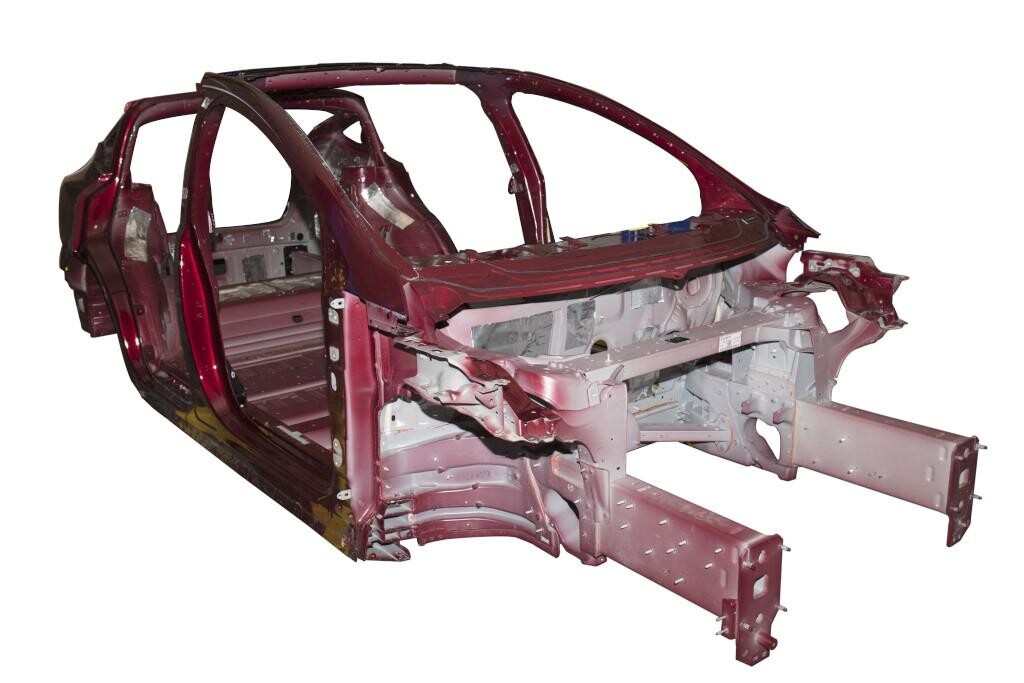

The donated data, including 3-D CAD drawings of structures, measurements, feature alignment, electronics, chassis properties and simulation models of current electric vehicles, is assisting the Midwest Roadside Safety Facility in its pursuit to make roads safer and reduce driver and passenger fatalities. As more electric vehicles are produced and purchased, exploring the interaction between these vehicles and roadside safety systems to ensure occupants remain safe in the event of a crash is vital, said Cody Stolle, research assistant professor and assistant director of the facility.

Existing systems are not designed to handle electrical vehicles which have unique undercarriage and frame structures, and which can weigh up to 50% more than gas vehicle counterparts. Updating barrier designs to accommodate electric vehicles could save hundreds of lives each year.

“We’re thrilled to receive this donation from Caresoft and for the safety benefits we expect to see as a result,” said Stolle. “We aim to develop a forgivable roadside; when a run-off-road crash occurs, we want to mitigate the severity of the crash and ensure vehicle occupants survive.”

Researchers are using Caresoft’s vehicle data to investigate dynamics and interactions between vehicles and roadside barriers, refine advanced computer simulation models of vehicle systems, and correlate crash outcomes with component designs and assemblies on vehicle makes. The data will also provide more complete knowledge for “in-service performance evaluations,” which relate real-world crash outcomes and vehicle impact conditions with roadside barrier design, performance and geometries.

A College of Engineering undergraduate student, Samantha White, is performing a research that compares electric and gas vehicle structures, inertial properties and frame designs under a Darrel J. Nelson Undergraduate Internship. This study, the first of its kind in the U.S., has data from 12 state departments of transportation, spanning the highest sales volume of electric vehicles.

Acquiring this data is a huge boon for the Midwest Roadside Safety Facility, said Stolle, especially as vehicle manufacturing and design are fast-paced, competitive industries. Vehicles are constantly changing, and it is difficult to ensure roadside safety hardware is prepared to handle past, current and future vehicle designs. By observing current-year production vehicles and anticipating changes in structural design and shape, researchers can quickly react to updates in the vehicle fleet and provide guidance for state department of transportations.

Stolle will also be helping focus national attention to safety issues regarding electric vehicles during the annual summer meeting of the Transportation Research Board Subcommittee on Roadside Safety in August in Kansas City, Missouri.

The Midwest Roadside Safety Facility, part of the University of Nebraska-Lincoln, is a research organization researching all aspects of highway design and safety. Its researchers conduct safety performance evaluations of various roadside appurtenances, developing new and innovative design concepts and technologies in the area of highway safety.