· 4 min read

City Campus cooling tower project enters final phase

A major upgrade to UNL’s City Campus heating, ventilation and air conditioning system enters its final phase this week.

Designed to increase the efficiency, redundancy and capacity of the campus heating/cooling system, the project is replacing two of the three cooling towers at the 14th and Avery streets utility plant. The first redesigned tower went online in fall 2013, while the second will be rebuilt this summer and start operating in the fall.

“The cooling tower system at the plant has been troubled with reliability issues for years due to the age and condition of the infrastructure,” said Charlie Griesen, utility project manager for Facility Planning and Construction. “This is the final phase of a multi-year effort to replace key components that the campus relies on for air conditioning of buildings.”

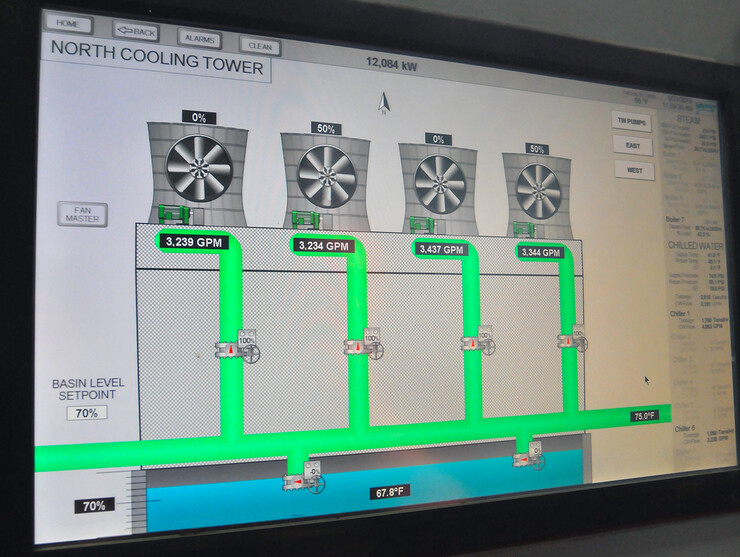

The City Campus system includes three cooling towers that remove heat from water used in the HVAC system. Inside the towers, nozzles spray water (up to 69,000 gallons per minute for all three towers) evenly through a specialized plastic material that is six feet thick. As the water flows through grooves in the plastic, giant fans draw air up and through the system. The upward flowing air helps draw heat out of the descending water, which pools in a concrete water basin before being drawn back into the HVAC loop.

Griesen said the new cooling towers use a plastic material with a counter-flow design, which allows for more efficient removal of heat.

“The cooling tower is designed so that water leaving a counter-flow tower is 10 to 15 degrees cooler than when it entered,” Griesen said. “During the summer, water enters cooling tower at about 90 degrees Fahrenheit and exits at 75 degrees. In the winter, the water can leave the tower as cool as 50 degrees.”

The new design also includes four cells in each tower that can be individually operated to meet demand or to allow for repair/maintenance. Previously, the two towers ran on an all-or-nothing design, which required a complete shutdown for repairs.

When complete, the newest tower, located by the sidewalk on 14th Street, will look different than the other two cooling units. Griesen said, where a corrugated fiberglass product was previously used on tower exteriors, UNL has opted for a double-wall design that will look more like architectural siding. The exterior wall will also extend to what was previously an exposed rail at the top of the tower to hide mechanical equipment.

“As this tower is the most visible, we decided to dress it up a bit,” Griesen said. “It’s definitely going to have more of an architectural look and feel.”

The next phase of work on the new $2.5 million tower is scheduled to begin May 27. This part of the project will include a temporary lane closure on 14th Street. A center turn lane will be used to allow traffic to continue to flow south toward Vine Street.

The tower will be brought online in the fall after it is connected to water and power lines.

For more information on the project, click here.